Exhaust Muffler Training

October 20, 2025

Exhaust Muffler Training

October 20, 2025In the competitive world of automotive manufacturing, cost efficiency is just as critical as performance. Mufflers, essential for noise control and engine efficiency, often involve complex manufacturing processes—especially in commercial vehicles where production volumes are high. This article summarizes a research study that successfully redesigned a commercial muffler to reduce production costs by over 77%, while maintaining acoustic and flow performance.

Redesign Strategy: From Complexity to Efficiency

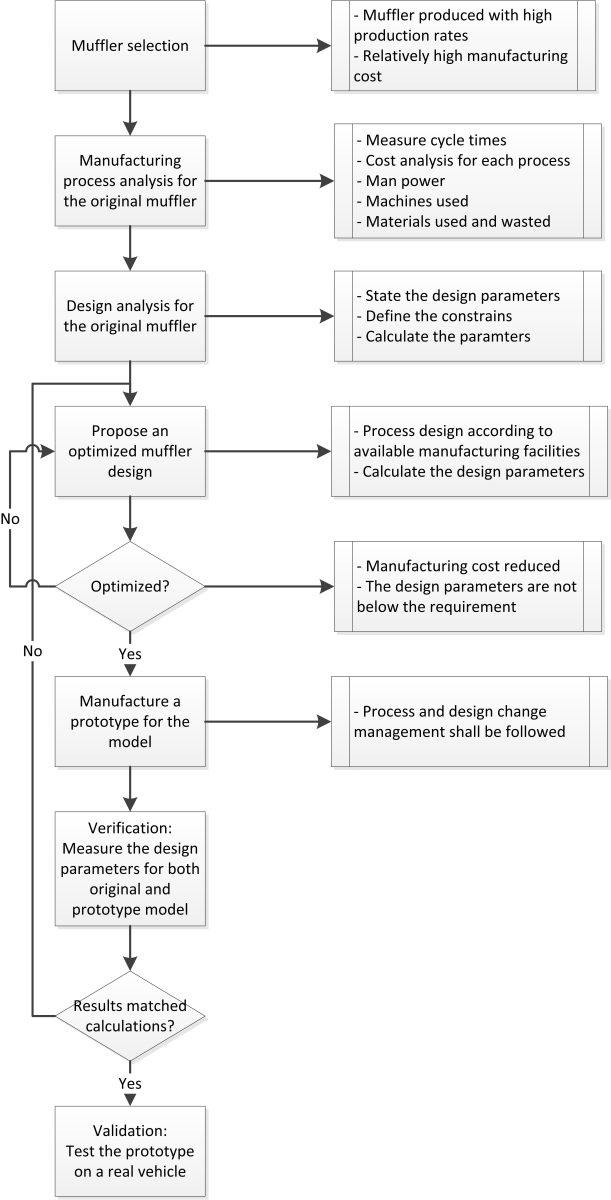

- Selection of a baseline muffler model (Type A) with high production complexity.

- Analysis of manufacturing steps, identifying bottlenecks such as perforated tube fabrication.

- Simulation of acoustic and flow parameters using SIDLAB and transfer matrix methods.

- Design simplification by reducing the number of internal components.

- Experimental validation of the new design (Type B) through transmission loss, pressure drop, and flow noise measurements.

- Iterative optimization, including the addition of damping material (rock wool) to enhance performance at specific frequency bands.

Flowchart outlining the steps from design analysis to experimental validation

This structured methodology ensures that the redesign is not only cost-effective but also compliant with industrial standards such as ISO/TS 16949:2002, which governs product realization in automotive manufacturing.

Why Muffler Design Matters

- Environmental compliance (noise regulations)

- Engine backpressure

- Passenger comfort

- Manufacturing complexity and cost

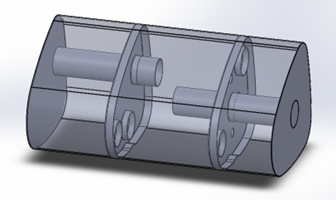

The Challenge: Type A Muffler

- Three perforated pipes

- Multiple chambers and baffles

- 18 manufacturing steps

Type A Muffler - Perforated tubes require extensive processing, increasing muffler cost

The Solution: Type B Muffler

- Using two Helmholtz Resonator Chambers

- Using the middle chamber as an Expansion Chamber with Quarter wavelength Resonators.

- Just three manufacturing steps

Type B uses fewer components to reduce manufacturing complexity

Performance Evaluation

1. Transmission Loss (TL)

\[

TL = 10 \log_{10} \left( \frac{1 + M_1}{1 + M_2} \right)^2 \cdot \left| \frac{Z_2}{Z_1 T_{11} + T_{12} Z_2 + Z_1 T_{21} + T_{22} Z_1 Z_2} \right|^2

\]

- : Transmission Loss [dB]

- M1,M2: Mach number at inlet and outlet

- Z1,Z2: Characteristic impedance at inlet and outlet

- Tij: Transfer matrix coefficients

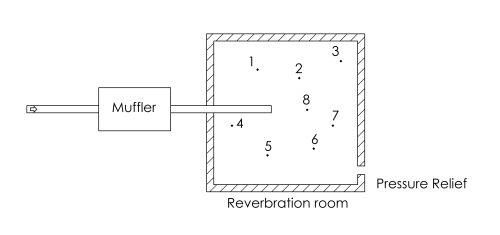

TL measured using SIDLAB and decomposition method with six microphones

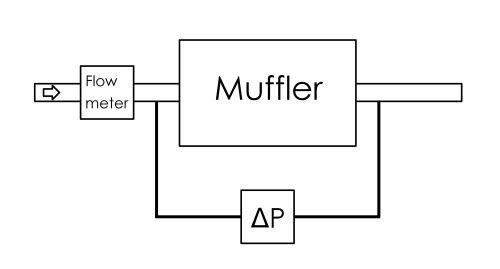

2. Pressure Drop

Z = \frac{\rho c}{A}

\]

- : Characteristic impedance [Pa·s/m³]

- ρ: Fluid density [kg/m³]

- c: Speed of sound [m/s]

- A: Cross-sectional area [m²]

Static pressure measured across muffler to evaluate flow resistance

3. Flow-Generated Noise

- : Flow resistance [Pa·s/m³]

- ke: Flow loss coefficient (dimensionless)

- ρ: Fluid density [kg/m³]

- : Cross-sectional area [m²]

- : Volume flow rate [m³/s]

Results at a Glance

| Parameter | Type A | Type B |

|---|---|---|

| Manufacturing Steps | 18 | 3 |

| Production Time | High | Reduced by 79% |

| Transmission Loss | Stable | Comparable |

| Pressure Drop | 2659.6 Pa | 3336 Pa |

| Flow Noise | Higher at HF | Lower at HF |

Conclusion

Download the Full Research Paper

👉 Production cost development for commercial exhaust systems

https://doi.org/10.1016/j.asej.2017.09.003

Contact Us

We'd love to hear from you! Whether you have questions, need a consultation, or want to discuss a project, feel free to reach out.